Do you specify A356 aluminum alloy for your aluminum castings?

If so, you probably know this alloy comes from Canada and is now being hit with a hefty tariff.

So the big question is:

Is there another alloy that’s close to A356 I can use instead—so I can avoid the current tariff?

Let’s talk about it.

Why A356 Is So Popular?

A356 has a lot of great qualities, but the main reason it’s used is for its higher magnesium content, which improves strength and—most importantly—machinability.

Here at Precision Enterprises, we machine over 90% of the castings we pour in our foundry division. So we’ve always appreciated how well A356 cuts. It’s been a go-to for foundries producing castings for automotive, aerospace, and industrial applications, especially where tight tolerances and post-casting machining are required.

But now…

Tariffs on A356 Have Doubled

As of June 4, 2025, the U.S. government doubled tariffs on imported aluminum from 25% to 50% under Section 232 of the Trade Expansion Act.

That’s made a major impact on the cost of castings that use A356—especially for high-volume, machined parts.

Are there other alloys you should be considering?

At Precision Enterprises, we pour a wide variety of aluminum alloys daily. We also pour test bars regularly to ensure every metal is in spec and in compliance.

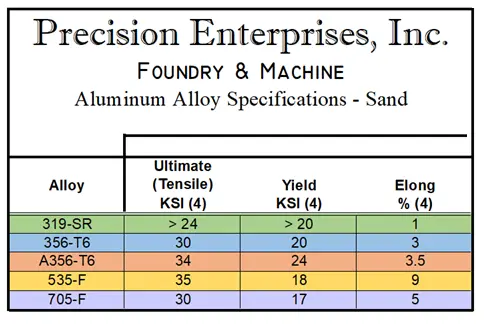

Here’s a chart showing a few alternative alloys that can replace A356, depending on your part’s requirements. See Our Full 2025 Engineering Guide: Aluminum Alloys here.

Take a close look at 535 alloy (commonly known as Almag).

Why Almag 535 Might Be a Better Choice

If you’re looking for tensile strength, Almag 535 is one to seriously consider. It’s one of the strongest aluminum alloysavailable for casting.

Now, we’ll be honest—the cost per pound is slightly higher than some other alloys.

BUT—and this is big—Almag doesn’t need to be heat treated.

That makes the overall cost well below A356, especially when you factor in the new 50% tariff.

Almag is also a naturally aged alloy. No extra processing. No wait time. No heat treat shop fees.

Another huge benefit?

Elongation.

This alloy will bend before it breaks.

Real-World Application: Medical Devices

We’ve partnered with several hospital product and medical manufacturers who rely on Almag for critical parts.

In fact, we supply the castings for a birthing bed. The stirrups that support a woman’s feet during labor?

Those are Almag castings.

Why? Because they don’t want catastrophic failure under extreme pressure.

Since Almag bends before it breaks, the birthing team can inspect for deformation between patients and catch any potential issues early.

Here’s the kicker:

We’ve never had a breakage in these castings in over 25 years.

What About My A356 Patterns?

Good news there too.

Patterns designed for A356 can usually be modified quickly and easily for other alloys.

In most cases, it’s just a minor gating change, and the pattern is ready to go for production.

More Than A Foundry – One Source, One Responsibility

If you’re trying to cut casting costs, avoid the A356 tariff, or just want to explore your options—we’re happy to help. You will not find a better home for all of your casting projects. We can promise you that! Take advantage of our 70 years of experience in casting and machining technology for cities all across the United States.

Give one of our casting experts a call. We can send you complete mechanical and chemical data on Almag and other alloys that can substitute for A356.

No responses yet