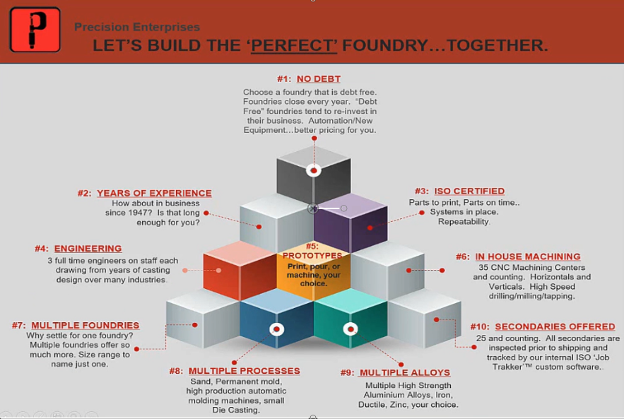

Considering Adding or Replacing a Foundry? Here’s What You Need to Know. Let’s build the perfect foundry together from the ground up.

Are you looking to add a new foundry to your operations or replace one that’s underperforming? Over the years, we’ve seen many new customers experience significant challenges and frustration as they navigated through the foundry selection process, only to ultimately find success with us. To help you learn from their experiences, we’ve put together a list of essential requirements and deal breakers when it comes to choosing the ideal foundry. Here’s a rundown of the top ten must-haves, which lay the groundwork for what constitutes a perfect foundry. All these factors contribute to selecting a supplier that meets a variety of needs.

1. No Debt

The number one deal breaker: Is the foundry debt-free? Foundries frequently go out of business, potentially taking your tooling, castings, fixtures, and hard-earned knowledge with them. A debt-free foundry is typically in a position to invest in new, advanced equipment, which translates to faster and more accurate production for you—the client.

2. Years of Experience

Experience Matters…Look for a foundry with at least 25 years of experience in casting. This skill is developed over many years through practice and isn’t simply a matter of luck or magic. Consistency and repeatability are crucial, and achieving these qualities takes significant time and expertise.

3. ISO Certified

ISO certification is another important indicator of reliability. It reflects that the foundry has documented its extensive experience and consistently applies this knowledge in its daily operations.

4. Engineering

A functioning engineering department ensures a second set of eyes that have years of foundry experience, and casting experience that your engineering department might not have.

5. Prototypes

The foundry must have processes that can supply your company with prototypes. These preproduction parts can guarantee your design, and in-house Machining invaluable before finalizing any expensive tooling prior to production runs. Print, pour, or machine…your choice!

6. In-House Machining

In-house machining…invaluable. In-house machining guarantees not only part functionality but, in many cases, fit and finish prior to production. Remember, in-house machining…not contracted out.

7. Multiple Locations

Dedicated Facilities! The perfect foundry should have multiple buildings or locations dedicated to specific casting processes or alloy family. This setup minimizes the risk of cross-contamination between different alloys. Each process requires specialized attention, which is why the foundry must allocate dedicated facilities for them.

8. Multiple Processes Casting Processes Offered

Casting Processes. Look for someonethat offers more than just one casting process. That way they will be able to advise you as to what casting process is the ‘best fit’ for your individual part. Quantity, size, wall thickness, and finish, to name a few, will certainly affect the final casting process you should consider for your part.

9. Multiple Alloys

Several foundries only pour 1 or 2 alloys. Many times, it is a consequence of having only 1 or 2 furnaces. This is a major problem that can lead to cross-contamination. Look for a foundry that has several dedicated furnaces. Precision Enterprises has multiple dedicated furnaces at each of its foundry locations. This solves the problem of cross-contamination while also being able to provide their customers with a huge selection of alloys to choose from.

10. Multiple Secondaries Offered

Secondaries. A great foundry will offer multiple secondary operations effectively. If managed properly, this can save you considerable time and costs, not to mention sparing you the headache of dealing with having to place multiple POs and expediting multiple vendors. Look for a foundry offering 1 source – 1 responsibility. That’s Precision Enterprises!

Key Takeaways

We hope our ‘Top 10’ list equips you with the tools you need to make an informed decision when searching for a new foundry or replacing an underperforming one. Choosing the right foundry is a challenging task, but with this knowledge, you no longer must settle for less than the best.

No responses yet