The process of Casting Aluminum …

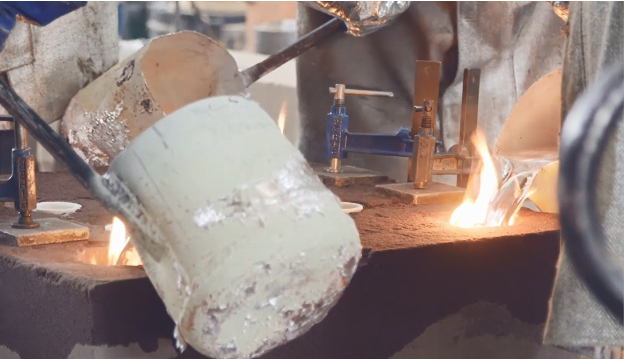

Casting Aluminum is a process where molten metal is poured into a mold to create a specific shape. The metal is melted in a furnace until it becomes liquid. The molten metal is then poured into a mold, which contains a hollow cavity created by the pattern of the desired shape. The metal is allowed to cool and solidify within the mold. Once solidified, the casting is removed from the mold. This final process is referred to as shake-out.

The Best Method of Casting Aluminum

The best method for casting aluminum is sand casting. The benefits are numerous. Low cost, short time to market, inexpensive tooling, good surface finishes, and several other valuable characteristics. Tooling used in the sand casting process has come a long way over the past years. Learn more about sand casting here.

Aluminum alloys

There a few common aluminum alloy types that are best suited for casting. Each alloy has its own compositions and properties that make it useful for certain applications. Select an alloy below to learn more.

4 Types of Aluminum Casting Foundries

There are four main types of aluminum casting foundries, depending upon which type of mold is used to either make the impression that creates the casting or the actual cavity that the molten metal is poured into. Precision Enterprises is a sand casting foundry.

- Sand Casting Foundries

- Die Casting Foundries

- Permanent Mold Casting Foundries

- Investment Casting Foundries (aka Lost Wax Casting)