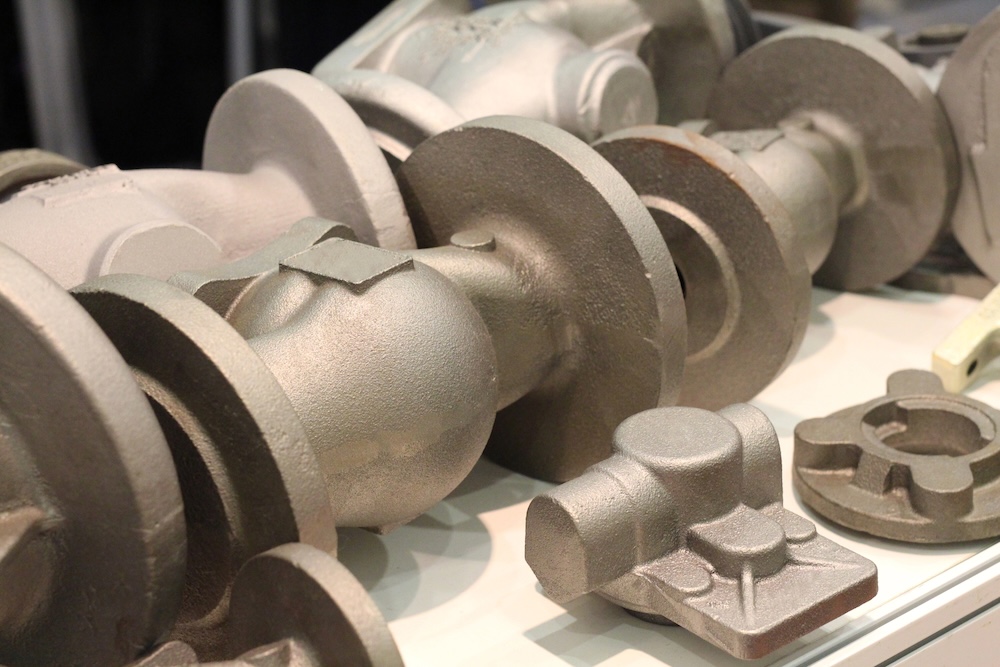

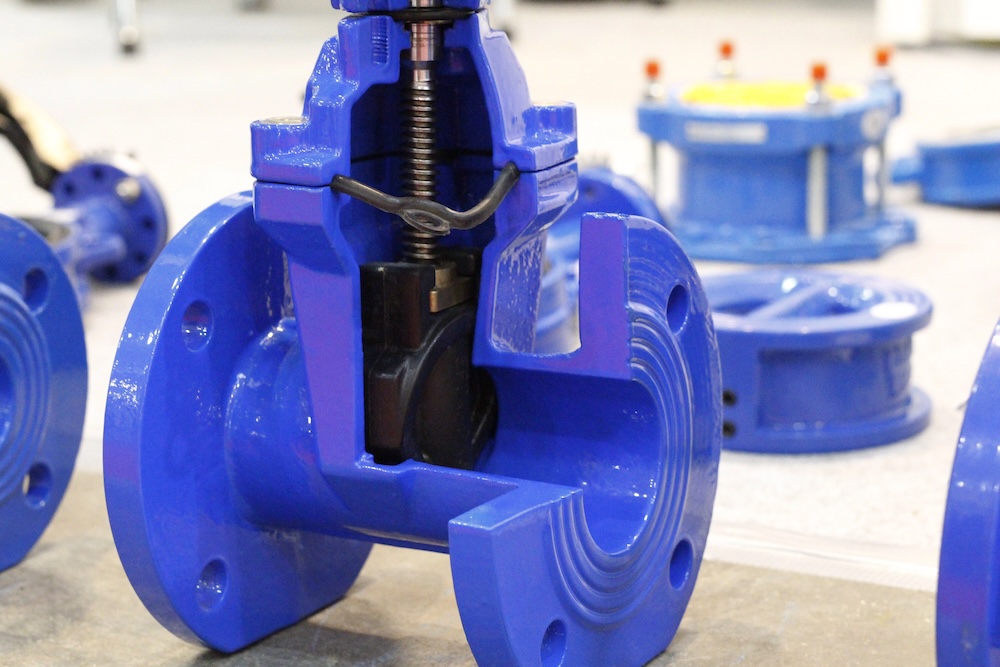

Grey & ductile Iron

At our foundry, we’re proud to offer more than just high-quality aluminum castings—we also pour grey and ductile iron. These types of iron are strong, durable materials used in a wide range of industrial parts and machinery. Whether you need strength, wear resistance, or performance under pressure, iron might be the right fit for your project. We use advanced simulation technology to ensure each casting is poured under ideal conditions, helping you get reliable, high-performance parts—every time.

How it works

We operate two 5 metric ton electric induction furnaces. Iron is heated to a temperature of close to 2,800° F and poured into molds at a temp between 2,400° F to 2,600° F.

MAGMASOFT is the software that we use to provide a simulation prior to pouring any new iron castings. We put all new tools through these simulations in order to find the best pouring conditions for your particular casting.

Available Materials

Iron Type

Gray Iron, ASTM A-48

Ductile Iron, ASTM A-536

Austempered Ductile Iron, A-897

Grade 1

Grade 2

Grade 3

Grade 4

Grade 5

Classification & Specification

Class 30

Class 35

Class 40

60-40-18

65-45-12

80-55-06

100-70-03

125-80-10

150-100-07

175-125-07

200-155-01

230-185-00

Tensile Strength (psi)

30,000

35,000

40,000

60,000

65,000

80,000

100,000

125,000

150,000

175,00

200,000

230,000

Brinell Hardness Range (BHN)

187-241

207-255

217-269

170 Max

156-217

187-255

241-302

269-321

302-363

341-444

388-477

444-555

Need an aluminum foundry?

You will not find a better home for all of your casting projects. We can promise you that!