Cores & Core Boxes Definition

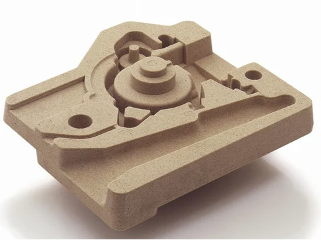

A core box is a tool/mold used in a foundry to create cavities or hollow spaces. The core box is essentially a mold used to form the cores. The core is placed inside the mold to create cavities or complex shapes in the casting itself. Core boxes are made from a variety of materials. Most sand foundries use wood, aluminum, or steel.

Wood Core Boxes

These boxes are usually for low production since these cores are made by hand. The process is very time consuming, and the core usually has to be filed to final shape. These core are solid and can be very difficult to remove from the solidified casting.

Aluminum or Steel Core Boxes

These boxes are good for high production. These boxes are known as shell core boxes and are made in 2 halves. Shell core machines blow core sand into these heated boxes under pressure, and the sand migrates to the outside of the box and is heated/baked into the final core. Little to no additional work needs to be done to these cores. Since the shell core is hollow, (think of an eggshell without its contents), the shell core is very easy to remove from the casting during shakeout.